Basic Data

Basic Type:

1.Insulated single conductor style

2.Twin conductor style

3.Un-insulated cord end sleeves

Characteristics

Total cross-section: 0.25~150mm²

Color-coding and tube dimension to DIN 46228, part 4(0.5~50mm²)

Halide free, Flame retardant can accept

Heat resistant to 105℃(PP) 120℃ (PA)

Material:

99% pure Copper

Synthetic: Polypropylene(PP), Polyamide(PA)

Surface

Tin-plated to protect against corrosion

Order info

Now also available in handy plastic boxes for smaller requirements. Under normal circumstances we do not have MOQ requirement for bag packaging.

Technical Data

Conductive Material(except Quick Connect Range)

|

Copper |

99.9% pure |

|

Tensile Strength |

200MPa |

|

Ductile Rating |

35% |

|

Final Metal State |

Part of the product annealed |

|

Oxygen Content |

50ppm max |

|

|

|

|

Brass |

30% Zinc 70% Copper |

|

Tensile Strength |

580 Mpa |

|

Ductile Rating |

6% min |

|

Final Metal State |

Part of the product annealed |

|

|

|

|

Material |

Tin |

|

Tin Content |

99.90% |

|

Other Metals |

Lead + Antimony |

|

Plating Thickness |

1.5 microns |

|

|

|

|

General Conductivity |

98.5% IACS |

|

Total Resistivity |

1.738 micro-ohm cm |

|

|

|

|

Material |

PVC for all except nylon 6 or nylon 66 – for IQC |

|

Breakdown voltage |

1.5 k V(min) |

|

Insulation resistance |

Above 100 meg ohms |

|

Working voltage |

Up to 300V AC/DC |

|

|

|

|

Pre-Insulate |

-40℃ to +150℃ |

|

Brass |

145℃ |

|

Tin plated |

160℃ |

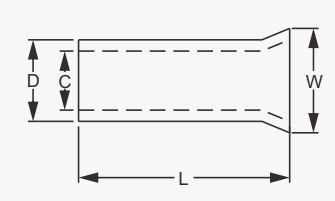

SPECIFICATION

|

Cross section (mm²) |

Item No. |

Dimensions(mm) |

A.W.G |

|

Cross section (mm²) |

Item No. |

Dimensions(mm) |

A.W.G |

||||||

|

L |

W |

D |

C |

|

L |

W |

D |

C |

||||||

|

0.25 |

EN0206 |

6 |

1.5 |

1.1 |

0.8 |

#26 |

|

10 |

EN10-18 |

18 |

5.8 |

4.9 |

4.5 |

#8 |

|

EN0208 |

8 |

|

EN10-20 |

20 |

||||||||||

|

0.34 |

EN0306 |

6 |

#24 |

|

EN10-25 |

25 |

||||||||

|

EN0308 |

8 |

|

16 |

EN16-12 |

12 |

7.2 |

6.2 |

5.8 |

#6 |

|||||

|

0.5 |

EN0506 |

6 |

1.7 |

1.3 |

`1.0 |

#22 |

|

EN16-16 |

16 |

|||||

|

EN0508 |

8 |

|

EN16-18 |

18 |

||||||||||

|

EN0510 |

10 |

|

EN16-20 |

20 |

||||||||||

|

EN0512 |

12 |

|

EN16-22 |

22 |

||||||||||

|

0.75 |

EN7506 |

6 |

1.9 |

1.5 |

1.2 |

#20 |

|

EN16-25 |

25 |

|||||

|

EN7508 |

8 |

|

25 |

EN25-12 |

12 |

9.1 |

7.9 |

7.5 |

#4 |

|||||

|

EN7510 |

10 |

|

EN25-16 |

16 |

||||||||||

|

EN7512 |

12 |

|

EN25-18 |

18 |

||||||||||

|

1.0 |

EN1006 |

6 |

2.2 |

1.7 |

1.4 |

#18 |

|

EN25-22 |

22 |

|||||

|

EN1008 |

8 |

|

EN25-25 |

25 |

||||||||||

|

EN1010 |

10 |

|

35 |

EN35-16 |

16 |

10.2 |

8.7 |

8.3 |

#2 |

|||||

|

EN1012 |

12 |

|

EN35-20 |

20 |

||||||||||

|

EN1018 |

18 |

|

EN35-25 |

25 |

||||||||||

|

1.5 |

EN1508 |

8 |

2.5 |

2.0 |

1.7 |

#16 |

|

50 |

EN50-12 |

12 |

12.7 |

10.9 |

10.3 |

#1 |

|

EN1510 |

10 |

|

EN50-18 |

18 |

||||||||||

|

EN1512 |

12 |

|

EN50-22 |

22 |

||||||||||

|

EN1518 |

18 |

|

EN50-25 |

25 |

||||||||||

|

2.5 |

EN2506 |

6 |

3.3 |

2.6 |

2.3 |

#14 |

|

70 |

EN70-22 |

22 |

15.8 |

14.3 |

13.5 |

2/0 |

|

EN2508 |

8 |

|

EN70-25 |

25 |

||||||||||

|

EN2510 |

10 |

|

EN70-32 |

32 |

||||||||||

|

EN2512 |

12 |

|

95 |

EN95-25 |

25 |

17.3 |

15.6 |

14.8 |

3/0 |

|||||

|

EN2518 |

18 |

|

EN95-30 |

30 |

||||||||||

|

4 |

EN4009 |

9 |

3.9 |

3.2 |

2.8 |

#12 |

|

EN95-34 |

34 |

|||||

|

EN4012 |

12 |

|

120 |

EN120-30 |

30 |

20.2 |

17.7 |

16.7 |

4/0 |

|||||

|

EN4018 |

18 |

|

EN120-34 |

34 |

||||||||||

|

6 |

EN6010 |

10 |

4.7 |

3.9 |

3.5 |

#10 |

|

EN120-38 |

38 |

|||||

|

EN6012 |

12 |

|

150 |

EN150-32 |

32 |

23 |

20.6 |

19.6 |

250/300 |

|||||

|

EN6018 |

18 |

|

EN150-40 |

40 |

||||||||||

|

10 |

EN10-12 |

12 |

5.8 |

4.9 |

4.5 |

#8 |

|

185 |

EN185-32 |

32 |

23.9 |

21.4 |

20.2 |

300/350 |

|

EN10-16 |

16 |

|

EN185-40 |

40 |

||||||||||